- Cookie Settings

- +49 (0)7223 9126800

- support@bailaho.net

The headquarters of the TELSONIC Group is located in Bronschhofen, Switzerland. More than 250 highly-qualified employees, individual affiliates in Germany, Serbia, England, America, China and specialized distributors support the application and process development of our customers in the application of our ultrasonic technology.

TELSONIC supports the research and basic development for the usage of ultrasonic technology through its activities at universities in Switzerland and in Germany. Quality is important to us. Ultrasonic is nearly omnipresent in the initial stages of production for articles made of plastic and metal or during their final assembly and thus, TELSONIC is an absolute specialist in regards to industrial ultrasonic technology.

We are certified according to ISO 9001 (SQS) and apply the principles of lean production. Our technical documentations, or their translations, are developed in accordance with ISO/DIS 17100 and support our globally active customers in the qualified application of our ultrasonic systems. Countless patents in the area of the industrial application of ultrasonic prove our innovative power, since 1966.

Products

Ultrasonic cleaning generators ECO ©

Reliability in a compact design

The advantages at a glance:

- Clearly and reliably compactly installed

- High operational safety

- Maintenance-free

Industries

- Engineering

- Automotive

- Battery

- Consumer Goods

- Food

- Medical

- Textile

- Packaging

Engineering

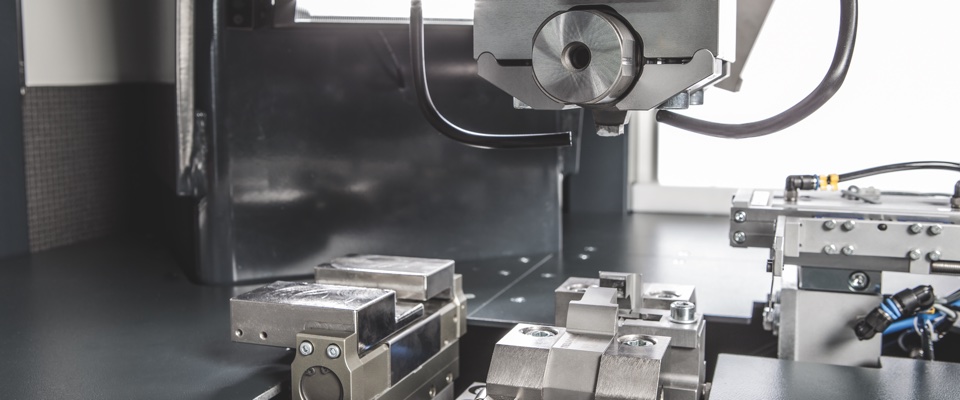

System engineering systems for machine engineering, for 50 years, we have been producing complete systems and components for the industrial usage of ultrasonic in system engineering. We supply international leading system engineering companies in many industries with our products and services.

Automotive

In the automotive industry, ultrasonics are particularly used for joining interior plastic parts, welding wires and contacts on cable looms, cleaning parts in the production process and for the screening of powder coatings.

Battery

Ultrasonic joining methods are widely used in the manufacture of batteries to ensure perfect electrical conductivity of connections, even between different metals. Furthermore, ultrasonic technology is used to screen powder for active coatings.

HandyStar Energy: The flexible ultrasonic hand welding unit

The HandyStar Energy is designed for simplicity and cost efficiency. It meets the requirements of manual workstations thanks to its robust construction. With 600 W peak power and 375 W continuous power, the HandyStar Energy can be used for a variety of 35 kHz applications. Typical applications are spot welding, riveting, crimping, and cutting.

Telsonic Secures Two New Prestigious Innovation Awards

Telsonic Group has an impressive heritage dating back to 1966. Throughout the years, the company’s philosophy of ongoing product development and innovation has been instrumental in establishing and maintaining a lead over its competitors.

Events

Company TELSONIC AG from 9552 Bronschhofen Bailaho: The company TELSONIC AG offers products and services like Innovations, Soniqtwist, PowerWheel, MAG Generator und MT8000. Send an inquiry o this company to set the first steps in a business contact. Please let the company know that you found them on Bailaho.

Monday : 08:00 - 17:00

Tuesday : 08:00 - 17:00

Wednesday : 08:00 - 17:00

Thursday : 08:00 - 17:00

Friday : 08:00 - 17:00

Scan the QR code to call up the company profile on your smartphone.